Rotary hearth furnaces/ Roller hearth furnaces/ Special furnaces

Home Products & Processes Rotary hearth furnaces-Roller hearth furnaces-Special furnaces

Rotary hearth furnaces/ Roller hearth furnaces/ Conveyor furnaces/ Special furnaces

-

Individual production

-

Most modern thermal insulating materials

-

Efficient heating systems

-

Latest control systems

Rotary hearth chamber furnace

These furnaces are primarily used for heating processes that run intermittently. Higher temperatures, but also low temperatures, are often realised in connection with downstream curing processes.

The heating system is designed depending on the power requirements. For this reason, the furnaces are often heated with gas.

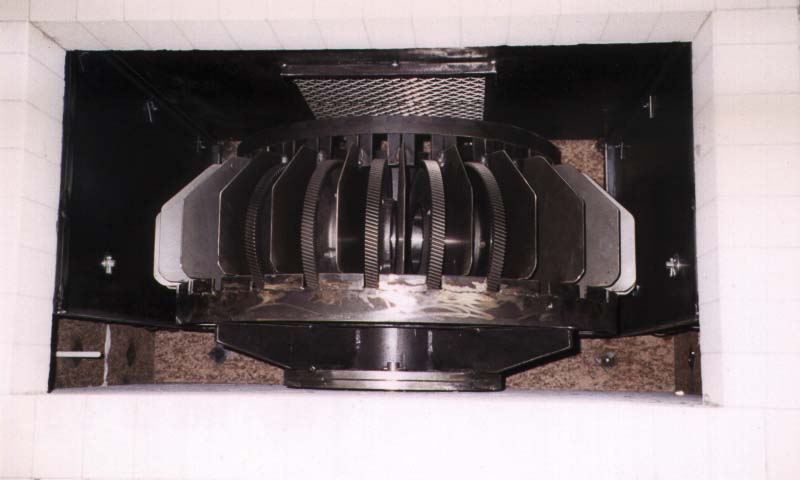

The picture shows one of the smallest "representatives" of this category of furnaces. This furnace is heated electrically due to its low temperature with a small charging capacity, and it is equipped with an air circulation device. A charging frame for gears is mounted on the rotary hearth. If required, this can also be changed completely. Feeding of the furnace takes place through a small bulkhead which is additionally secured with a light barrier. The rotary hearth drive is located under the furnace.

Special furnaces / Chamber furnaces

Given the multiplicity of application processes, there is need to come up with new solutions time and again.

New technologies often require new system plant designs, but even the economic requirements that are constantly becoming more flexible, the ever changing batches etc present new demands. Therefore we manufacture plants heated with gas or electricity with or without protective gas.

The furnace shown in the picture with two cooling chambers mounted on the right and left is for the two-way heating of special materials under protective gas. A maximum furnace room temperature of 950 °C can be realized. The entire plant can be moved on both sides on the railway track.

Roller hearth furnaces

Roller hearth furnaces are often used for heating geometrically simple raw material, e.g. metal sheets, discs, rods etc., for forming processes. At the same time this process is used not only in the metalworking industry but also for non-ferrous materials like ceramic, glass, plastic materials etc.

Due to the very modern materials, high temperatures are now possible. Efficient heating systems (powered by fuel electric heating) applied in a customised manner and in connection with the most modern control systems and handling system make these roller hearth furnaces interesting for serial processes.

The roller hearth furnaces are used in the convectional area as well as in the radiation zone, i.e. at high temperatures.